Remote Pipeline Monitoring Systems

Remote pipeline monitoring systems play a crucial role in enhancing the safety, reliability, and performance of industrial assets and equipment. By leveraging real-time data from production assets, these systems help organizations minimize unplanned downtime, optimize maintenance schedules, and improve overall asset reliability.

Industries that rely on extensive equipment deployed across remote locations—such as oil and gas, utilities, mining, and manufacturing—can greatly benefit from remote pipeline monitoring solutions. These systems provide continuous oversight, allowing businesses to track asset locations, monitor performance metrics, and detect issues as they arise. With automated alerts and real-time notifications, organizations can respond swiftly to critical events without the need for immediate field personnel intervention, reducing operational risks and costs.

Additionally, remote pipeline monitoring solutions integrate with advanced analytics and predictive maintenance technologies, enabling data-driven decision-making. By identifying patterns and potential failures before they occur, businesses can proactively address maintenance needs, extend equipment lifespan, and enhance operational efficiency. This level of insight empowers companies to maintain higher productivity levels while ensuring the safety of both personnel and assets.

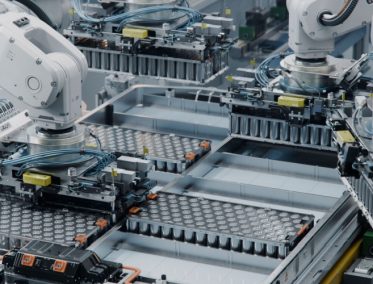

Remote Pipeline Monitoring Architecture

Example Use Case – Remote Pipeline Monitoring Systems

Pipeline leaks can have devastating consequences, ranging from safety hazards and environmental damage to financial losses and reputational harm. Given the critical role pipelines play in transporting oil, gas, and chemicals, operators must implement reliable leak detection systems to minimize risks. These systems enable early detection, accurate leak localization, real-time alerts, and effective operations under challenging conditions, ultimately ensuring regulatory compliance and operational efficiency.

Consequences of Pipeline Leaks

Safety Risks

Pipeline leaks pose significant safety risks to workers, nearby communities, and emergency responders. Depending on the type of substance being transported, leaks can lead to fires, explosions, or toxic gas releases. For example, natural gas leaks create highly flammable conditions that can result in catastrophic incidents if ignited. Additionally, exposure to hazardous chemicals can cause respiratory issues, burns, or long-term health effects for those in proximity. Ensuring quick leak detection is essential to prevent such dangerous situations.

Environmental Risks

Environmental damage from pipeline leaks can be extensive, affecting ecosystems, water bodies, and air quality. Crude oil spills contaminate soil and water, killing aquatic life and rendering land unsuitable for agriculture or habitation. Gas leaks, such as methane emissions, contribute to climate change by releasing potent greenhouse gases into the atmosphere. Cleaning up environmental damage is not only costly but also time-consuming, often taking years to fully restore affected areas. This makes prevention and early detection of leaks a top priority for sustainable operations.

Property and Infrastructure Damage

Leaks can cause severe damage to infrastructure, including roads, bridges, and buildings located near pipelines. Corrosive substances can weaken metal structures, leading to pipe bursts and further deterioration. In urban areas, a gas leak can force evacuations and disrupt essential services, affecting businesses and residents. In extreme cases, undetected leaks can erode the ground beneath structures, causing sinkholes or foundation instability. Effective monitoring helps prevent costly infrastructure damage and ensures the longevity of pipeline networks.

Financial Costs and Regulatory Fines

Pipeline leaks can lead to substantial financial losses due to regulatory fines, legal liabilities, and operational downtime. Governments impose strict environmental and safety regulations, and non-compliance can result in multi-million-dollar penalties. Beyond fines, companies must also bear the costs of cleanup, compensation for affected communities, and repairing damaged pipelines. Moreover, production shutdowns caused by leaks can disrupt supply chains, leading to lost revenue and strained business relationships. Investing in advanced leak detection systems helps companies mitigate these financial risks.

Reputational Damage

A major pipeline leak can severely impact a company’s reputation, leading to public backlash, loss of customer trust, and scrutiny from investors. Negative media coverage can influence public perception, potentially leading to protests, stricter regulations, or even legal action. Companies known for frequent leaks may struggle to secure new projects, attract investors, or maintain long-term partnerships. Proactively implementing and showcasing effective leak detection measures can enhance a company’s image and demonstrate a commitment to safety and environmental responsibility.

Key Features of an Effective Remote Pipeline Leak Detection System

Detect Leaks Quickly

An effective leak detection system must be capable of identifying leaks as soon as they occur to minimize damage and operational disruptions. Technologies such as pressure monitoring, flow rate analysis, and acoustic sensors continuously track pipeline performance, detecting anomalies that indicate possible leaks. By analyzing deviations in real-time, these systems allow operators to respond swiftly, preventing small leaks from escalating into larger incidents. The faster a leak is detected, the lower the potential damage and associated costs.

Locate Leaks Accurately

Accurately identifying the location of a leak is critical for efficient response and repair efforts. Modern leak detection systems use various technologies, including computational pipeline monitoring (CPM), fiber-optic sensing, and negative pressure wave detection, to pinpoint leaks within a few meters. This precision reduces the time needed for field teams to locate and fix the issue, minimizing environmental impact and financial losses. Without accurate location tracking, response times can be delayed, leading to greater damage and higher remediation costs.

Receive Real-Time Alerts

Immediate alerts are essential for ensuring a prompt response to leaks, allowing operators to take corrective action before the situation worsens. Advanced monitoring systems integrate automated alarms that notify control rooms, field teams, and decision-makers in real-time through multiple channels, including mobile devices and cloud-based dashboards. These alerts provide critical details such as leak location, severity, and potential risks, enabling a well-coordinated and timely response. Without real-time notifications, leaks may go undetected for extended periods, increasing safety and environmental risks.

Operate Effectively Under Difficult Conditions

Pipeline networks often run through challenging environments, including remote areas, underwater locations, and extreme weather conditions. Leak detection systems must be designed to function reliably under these demanding circumstances. Redundant communication systems, AI-driven analytics, and rugged sensors ensure continuous monitoring, even in areas with limited access or harsh operating conditions. A robust system should also be able to differentiate between false alarms and real leaks, reducing unnecessary shutdowns and maintenance costs while maintaining operational efficiency.

Key Benefits of IoT-Based Remote Pipeline Monitoring Systems

Increase Productivity

According to Aberdeen Research, 82% of companies have experienced unplanned downtime over the past three years and this can cost a company as much as $260,000 an hour. Besides affecting your potential profit margin, it can also have adverse effects on delivery schedules and agreements with clients. With remote pipeline monitoring, you can ensure that all your assets and equipment are working as expected, maximizing your productivity.

Lower Maintenance Costs

Gartner estimates that decision automation in the form of predictive maintenance will generate the highest business value for organizations with heavy assets. Faulty machinery can lead to a ripple effect where other equipment in the ecosystem also malfunctions, causing further damage. These defects are virtually impossible to trace without the use of predictive maintenance techniques, making remote pipeline monitoring a useful investment for asset-intensive companies.

Increase Asset Lifespan

Remote pipeline monitoring enables you to monitor and maintain assets for better availability, utilization, and performance. You can gain better visibility into assets via real-time monitoring, allowing you to predict machine failure and identify parts that need replacement. You can schedule maintenance and repairs, predict events before they occur, and get real-time notifications that enable you to take quick action, thereby extending the life of your assets.

Improve Safety and Compliance

Remote pipeline monitoring systems enable companies to anticipate possible safety risks before they occur, allowing them to quickly take the necessary action to mitigate these risks. By monitoring and analyzing data over long periods, you can identify potentially hazardous conditions and estimate their impact on working conditions and the environment. By integrating remote monitoring systems with other business applications, you could then trigger instructions to take corrective measures and keep exposure levels below the threshold values, in compliance with regulations.

Gain Manufacturing Visibility

Remote pipeline Monitoring systems receive and process data from the factory floor to generate current views of factory operations and production line output. From a global overview down to the health of specific machines, up-to-date production status is readily available to production managers, machine operators, and floor supervisors. Create an accurate visual representation of your production environment, viewing your production operations at a global scale and providing visibility into production status for specific products or production lines.

Optimize Production Processes

Gathering shop floor data is pointless if customers can’t use it to drive efficiencies or optimize production processes. Remote pipeline monitoring systems analyze streaming data from the production floor to detect anomalies across machines, assembly lines, and factories. Floor managers can view live data and comparisons across machines and locations to quickly identify factories, lines, machines, and products that are underperforming and determine anomalies in their operations.

Improve Service Crew Productivity

Using sensor data collected directly from the production equipment, factory managers can quickly identify the reasons for machine underperformance or machine failures that are impacting production throughput. Detailed machine performance data enables factory floor workers to observe machine operation remotely and arrive on the scene properly equipped to repair the affected machines. Depending on equipment capabilities, operators may be able to remotely reset equipment, avoiding the need for time-consuming site visits.