Some critical warehouse management challenges include space constraints, inefficient inventory tracking, improper space utilization, and a lack of visibility into data and processes. Modern warehouse managers need access to real-time critical information to make smarter decisions, particularly when improving inventory accuracy and optimizing material handling.

An intelligent connected warehouse offers significant benefits by integrating advanced technologies such as IoT, AI, and automation to create a seamless, real-time flow of information and operations. This connectivity enables greater visibility across the entire supply chain, allowing for real-time monitoring of inventory, equipment, and workforce activities. With predictive analytics, warehouses can anticipate and prevent equipment failures, optimize material handling, and enhance worker safety. Automation and data-driven insights lead to faster order fulfillment, improved inventory accuracy, and reduced operational costs.

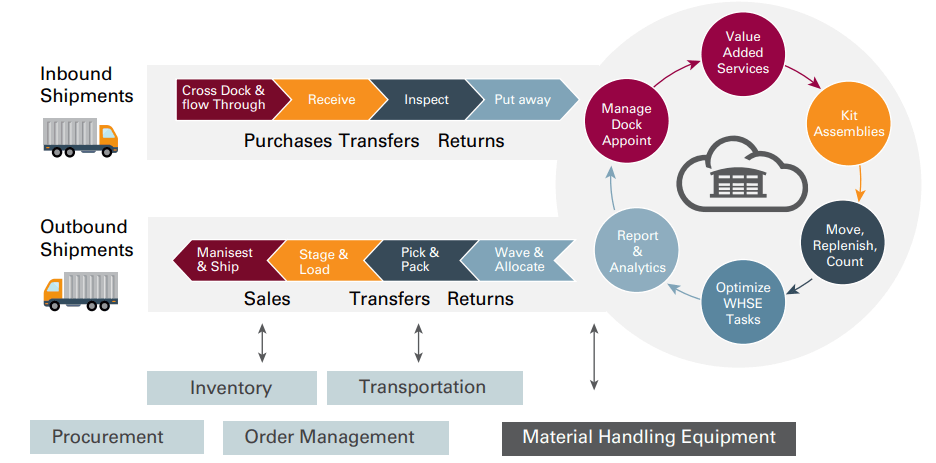

Modern Smart Connected Warehouse (Image Source: Oracle)

4 Features of Oracle Warehouse Management Cloud

Warehouse Performance Monitoring

Oracle Warehouse Management Cloud provides robust tools to track every aspect of your warehouse operations in real-time. This feature offers complete visibility into critical metrics such as inventory levels, order fulfillment times, and resource utilization. You can quickly detect anomalies by continuously monitoring performance data, such as bottlenecks in order processing or irregular stock movements. With early warnings of potential issues, you can make data-driven decisions to adjust workflows, improve resource allocation, and ensure operational efficiency. This level of oversight helps prevent costly delays and maintain optimal performance throughout your warehouse operations.

Predicting Warehouse Equipment Failure

Oracle’s predictive analytics capabilities allow for continuous monitoring of warehouse equipment such as conveyor belts, forklifts, and robotic systems. By tracking the health, usage patterns, and performance of these assets, the warehouse management system (WMS) can detect early signs of wear and tear. Predictive maintenance algorithms analyze this data to forecast when equipment may fail, enabling you to schedule repairs or replacements in advance. This minimizes unplanned downtime, reduces maintenance costs, and extends the lifespan of critical equipment. Proactive maintenance also ensures uninterrupted warehouse operations, leading to increased productivity and smoother logistics for material handling.

Worker Safety Monitoring

Oracle Warehouse Management Cloud integrates with sensors, cameras, and wearable devices to monitor the conditions around warehouse staff in real-time. The system can automatically identify potential safety risks by tracking movements, proximity to heavy machinery, or exposure to hazardous areas, such as forklift collisions or slips and falls. Safety alerts can be triggered in response, and appropriate measures, like equipment shutdowns or rerouting workers, can be implemented. By actively preventing accidents and promoting a culture of safety, this feature helps reduce workplace injuries and ensures compliance with safety regulations.

Quality and Compliance Monitoring

Oracle Warehouse Management Cloud provides tools to ensure that products meet stringent quality standards and regulatory compliance. This feature tracks each product’s lifecycle, from inbound shipments to final delivery, ensuring proper handling, storage conditions, and quality control checks are consistently maintained. The system flags deviations from preset quality standards, allowing immediate corrective action to prevent defects or product spoilage. Additionally, compliance monitoring ensures adherence to state and federal regulations, such as food safety or pharmaceutical standards, helping to avoid legal repercussions, fines, and recalls. This end-to-end traceability ensures inventory accuracy and that customers receive products that meet both quality and regulatory expectations.

Benefits of Oracle Warehouse Management Cloud

It provides complete inventory management from the manufacturing source to the end user, allowing you to source and fulfill orders from anywhere. Warehouse managers can use mobile devices to view real-time analytics and get complete visibility into inventory across distribution centers. They can also analyze labor productivity by comparing goals to actual performance. The solution combines the flexibility and savings of the cloud with best-of-breed functionality while giving businesses a complete view of their inventory without the high maintenance costs and upgrade challenges of traditional solutions.

Optimize Inventory Management

Oracle Warehouse Management Cloud can be used to manage materials and provide total inventory accountability and visibility, optimizing and automating warehouse operations with multi-channel fulfillment needs. The solution enables end-to-end inventory management and productivity improvements across the supply chain.

Increase Scalability

Integrating your current warehouse control systems with Oracle’s warehouse management cloud helps you create automated facilities. This improves efficiency, allows you to scale your warehouse operations quickly, and gives you the ability to serve customers faster.

Improve Workforce Management

Oracle Warehouse Management Cloud provides warehouse managers with greater visibility into their operations and workforce to help reduce labor inefficiencies, raise overall performance, and improve accuracy. It includes KPIs that manage and track workforce performance based on quantifiable goals.

Leverage Supply Chain Analytics and Dashboards

Oracle Warehouse Management Cloud offers powerful analytics and dashboards that enable real-time analysis, reporting, and alerting. You can build your own dashboards and reports, measuring KPIs for multiple warehouses and sourcing locations to enables real-time analysis of location utilization, and inventory etc.

Real-Time Insights from Connected Assets

Oracle IoT Asset Monitoring Cloud improves profitability through automated monitoring and alerting of assets. Businesses can gain real-time visibility into asset health and utilization and predict future events. Improve Worker Safety Oracle IoT Connected Worker Cloud helps ensure worker health and safety, achieve better regulatory compliance, and gain real-time visibility into worker health, location, and work environment.

Potential Outcomes of Deploying Oracle Warehouse Management Cloud

Reduce Warehouse Operating Costs

Oracle Warehouse Management Cloud helps lower overall operating expenses, including shipping and IT-related costs by improving labor productivity, reducing labor costs, optimizing equipment usage, and increasing storage capacity.

- 15% – 35% improvement in labor productivity: Automation and real-time tracking enable workers to complete tasks more efficiently, improving productivity.

- 10% – 25% reduction in labor costs: Optimized workforce management reduces unnecessary labor expenses through better task allocation and performance tracking.

- 10% – 20% increase in equipment usage: Predictive maintenance and real-time monitoring ensure that equipment is utilized more effectively, minimizing downtime.

- 10% – 25% increase in storage capacity: Improved space utilization and better inventory management allow for more efficient use of available storage.

- 5% – 10% reduction in expedited shipping costs: Better order management and fulfillment reduce the need for costly expedited shipping.

- 15% – 45% reduction in IT-related costs: Cloud-based infrastructure eliminates the need for expensive IT maintenance, hardware upgrades, and system overhauls.

Reduce Warehouse Inventory Costs

Oracle Warehouse Management Cloud reduces the costs associated with maintaining excess inventory, missing or damaged stock, and expired materials, resulting in more efficient inventory management.

- 15% – 30% reduction in safety stock: Accurate demand forecasting and real-time tracking help minimize excess stock while ensuring optimal inventory levels.

- 15% – 25% reduction in missing inventory: Improved visibility and tracking reduce the incidence of misplaced or lost inventory.

- 15% – 30% reduction in damaged material: Better handling practices and real-time monitoring reduce damage to goods during storage and transit.

- 15% – 45% reduction in expired material: Automated tracking of inventory life cycles helps prevent materials from expiring before they can be used or sold.

Increase Revenues

Oracle Warehouse Management Cloud boosts revenues by enhancing fulfillment accuracy, improving on-time deliveries, and increasing customer satisfaction.

- 0.5% – 2.5% increase in revenues: Better operational efficiency and customer satisfaction contribute to increased sales and revenue growth.

- 10% – 25% increase in on-time and full shipments: Streamlined processes ensure that orders are fulfilled accurately and delivered on time, leading to higher customer trust.

15% – 35% improvement in customer satisfaction: Faster, more reliable fulfillment and better service drive improvements in overall customer satisfaction.